Necessary Tips for Effective Drywall Fixing and Setup Strategies

Efficient drywall repair service and setup requires a cautious approach. Understanding the kinds of drywall and having the right tools is crucial. Proper techniques and exact measurements can considerably impact the end result. Several overlook important steps like taping and fining sand, which can make or break the final appearance. As jobs proceed, usual obstacles may arise that need interest. Checking out these pointers can bring about a much more successful and refined finish.

Understanding Different Sorts Of Drywall

Recognizing the numerous kinds of drywall is necessary for any kind of successful repair service or setup project. Drywall, typically called gypsum board, is available in numerous selections customized for certain applications. Criterion drywall is the most widely used kind, suitable for basic indoor walls and ceilings. Moisture-resistant drywall, typically eco-friendly in color, is created for areas prone to humidity, such as kitchens and washrooms. Fireproof drywall, typically colored pink or purple, is crafted to endure greater temperature levels and is typically made use of in garages or near heating systems. In addition, soundproof drywall assists decrease noise transmission, making it suitable for multi-family homes or taping workshops. Specialized drywall, like cement board, is made use of in wet areas like showers or tub surrounds. Recognizing these kinds helps in picking the ideal product for each task, making certain toughness and effectiveness in repairs or new setups.

Vital Tools for Drywall Repair and Setup

Having the right devices is necessary for effective drywall repair and setup. A high quality utility blade is important for reducing drywall sheets specifically. A drywall T-square assists guarantee straight edges, while a taping knife is essential for applying joint compound smoothly over seams. Additionally, a drywall saw enables removing damaged sections or suitable drywall around fixtures.

For hanging drywall, a power drill with drywall screws is important, as it makes it possible for safe and fast installment. A degree is likewise crucial to verify that the drywall is straight and effectively straightened. Once it has actually dried out, a fining sand block or post sander is necessary for smoothing out joint compound. A gauging tape is crucial for accurate measurements, preventing waste and making certain a proper fit. Furnished with these devices, people can take on drywall tasks properly, leading to professional-looking results.

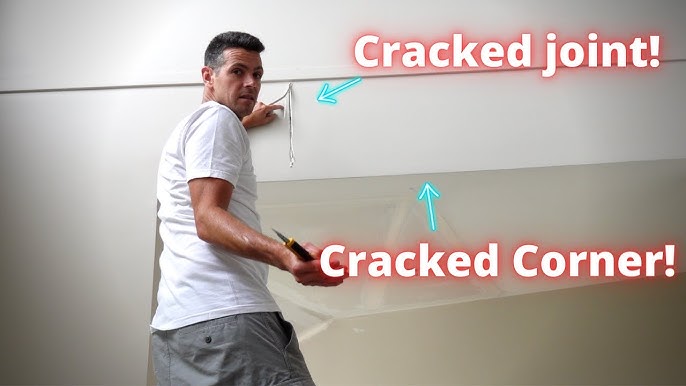

Step-by-Step Guide to Repairing Holes and Cracks

When dealing with openings and cracks in drywall, having the right tools and materials is vital for a successful fixing. This guide describes the needed things and offers a clear, detailed procedure to efficiently restore the surface. Understanding these aspects will help assure a smooth surface and resilient results.

Tools and Materials Needed

A well-appointed toolkit is vital for effective drywall fixing and installation. Trick tools include an energy blade for reducing drywall, a tape step to guarantee exact sizing, and a drywall saw for larger openings. A putty knife is crucial for using joint compound efficiently, while a sanding block or post sander aids accomplish a smooth coating. For patching, a roll of fiberglass harmonize tape or paper tape is required to reinforce joints. In addition, a drill and screws are required for protecting brand-new drywall pieces. Essential products are composed of joint substance, primer, and paint to complete the repair. Having these devices and products accessible guarantees a smoother, more effective repair process, producing professional-looking results.

Repair Refine Actions

Repairing openings and splits in drywall requires a methodical technique to guarantee a smooth finish. First, the area bordering the damages needs to be cleaned up completely to remove dust and particles. Next off, for tiny cracks, a putty knife is used to apply a joint substance evenly over the location. For bigger openings, a patch is needed; the harmed area is removed, and a new item of drywall is fitted in area, secured with screws. Once the spot remains in placement, joint substance is applied to mix the edges. After drying, sanding the location smooth is important. The fixed surface area ought to be primed and repainted to match the bordering wall surface, guaranteeing a low-profile repair work.

Techniques for Putting Up Drywall Panels

Mounting drywall panels needs careful preparation and exact implementation to assure a expert and smooth surface. Initially, it is important to determine the wall area precisely and reduce the panels to fit, guaranteeing that they line up with the studs. Positioning the panels horizontally is generally suggested, as this can enhance the architectural integrity and decrease the number of joints.

Utilizing drywall screws, installers should protect the panels every 16 inches along the studs, ensuring a company hold. It is vital to prevent overdriving the screws, which can damage the paper surface. For edges and sides, utilizing an utility knife permits clean cuts and a tight fit.

Completing Touches: Insulation, Mudding, and Fining sand

When the drywall panels are securely in area, the next essential step includes the finishing touches of taping, mudding, and sanding. Insulation is necessary for producing a seamless change in between panels and hiding joints. A high quality drywall tape, either paper or fiberglass harmonize, should be applied over the seams, guaranteeing it sticks appropriately to the mud that will be used next.

Mudding, or applying joint substance, complies with the taping process. This compound fills up spaces and smooths out the surface. A very first layer should be applied kindly, feathering the edges to blend with the drywall. After the preliminary layer dries, succeeding layers may be needed for a flawless finish.

Sanding is required to attain a smooth surface. A fine-grit sandpaper ought to be utilized to carefully smooth out any type of flaws. Care should be required to stay clear of over-sanding, which can damage the drywall - Drywall Installation Ogden Utah. Properly implemented, these ending up touches create a professional look all set for paint

Tips for Keeping Your Drywall After Setup

Maintaining drywall after installation is vital to protecting its appearance and structural stability. Routine cleaning is needed; dirt and dust can gather, so gentle wiping with a moist fabric is recommended. Home owners need to also check for any kind of signs of wetness or mold and mildew, especially in high-humidity areas like kitchen areas and shower rooms. If any type of damages occurs, it is very important to resolve it promptly to avoid additional concerns.

Making use of furniture pads can aid protect against scrapes or damages from more info heavy things. In addition, repainting the drywall with a high-grade, washable paint provides an added layer of protection and makes future cleansing easier. Stay clear of making use of unpleasant cleaners or tools, as these can harm the surface area. Maintaining a secure interior environment with ideal moisture levels will certainly help protect against splitting or contorting over time. By following these suggestions, one can ensure that drywall stays in excellent condition for years to find.

Regularly Asked Inquiries

The Length Of Time Does Drywall Require To Totally Dry After Installment?

Can I Mount Drywall Over Existing Drywall?

Yes, drywall can be installed over existing drywall, however it is essential to ensure the underlying surface area is safe and appropriately prepared. This method can enhance insulation and minimize installment time, though it may include weight.

What Is the very best Method to Soundproof Drywall?

The very best way to soundproof drywall entails making use of specialized soundproofing products, such as resilient networks, acoustic caulk, and sound-dampening drywall. These methods efficiently lessen audio transmission between areas, boosting overall acoustic efficiency in living areas.

Just how Do I Choose the Right Drywall Density?

To pick the right drywall density, take into consideration the application and area. Requirement residential walls generally use 1/2 inch, while ceilings or specialized areas may need 5/8 inch for extra stamina and soundproofing abilities.

Exist Eco-Friendly Drywall Options Available?

Yes, environmentally friendly drywall options are available. These include items made from recycled products, plaster boards with low unstable natural substances (VOCs), and those making use of sustainable manufacturing procedures, using environmentally-conscious options for building and construction and improvement jobs.

Having the right tools is important for efficient drywall repair service and installment. For hanging drywall, a power drill with drywall screws is essential, as it enables secure and fast installation. Secret tools consist of an energy blade for reducing drywall, a tape step to ensure precise sizing, and a drywall saw for larger holes. Yes, drywall can be installed over existing drywall, however it is important to guarantee the underlying surface is protected and sufficiently prepared. The ideal way to soundproof drywall includes utilizing specialized soundproofing materials, such as resistant channels, acoustic caulk, and sound-dampening drywall.